Types of Building Glass

Glass, this remarkable material that has become an integral part of our lives, finds diverse applications everywhere. From graphical beauty in interior decoration to insulation and light transmission in building facades, glass stands as one of the most essential elements in architecture and construction. Due to its unique properties, such as impact resistance, thermal and sound insulation, and transparency, glass is a marvel that seamlessly combines beauty and functionality. From plain glass to frosted, mirrored, light glass, etc., each type has its own unique features and uses, and we at Hooramco offer high quality, high-performance glass for you. Here is an explanation of the types of building glass:

- Plain float glass: This type of glass is manufactured in various thicknesses and is commonly used in windows and doors. Due to the impurities present during production, float glass has slightly lower transparency.

- Colored float glass: This glass is made by adding metal oxides to molten glass, giving it a variety of colors. Its high transparency and quality make it popular in construction and interior design, and it can be manufactured in different thicknesses.

- Super-clear glass: This type of glass has high transparency with minimal coloration. It is used in areas where greater clarity and visibility are required.

- Patterned glass: Patterned glass is often used in private spaces to prevent visibility from the outside while allowing adequate light to enter the interior. The patterns are engraved on the glass surface.

- Satin glass: This type of frosted glass is produced using abrasive acids like hydrofluoric acid. This process gives the glass a matte appearance and a satin-like texture, while still allowing light to pass through, though details behind the glass are blurred.

- Reflective glass: Reflective glass has mineral coatings that reflect sunlight outward. It is used in buildings to reduce thermal and solar glare.

Building glass reinforcement

Introduction to Plain Glass

Plain glass, known for its transparency and natural beauty, is a popular choice in the construction industry. Made from high-purity silica, plain glass offers unique features:

- High transparency: Allows complete, undistorted visibility.

- Ease of cutting and installation: Can be easily cut to desired dimensions.

- Recyclable: Plain glass is environmentally friendly and can be recycled.

- Affordable cost: More economical compared to other types of glass.

- Design flexibility: Suitable for various architectural projects.

Introduction to Tempered Glass

Tempered glass, one of the latest innovations in construction, plays a crucial role in enhancing security and aesthetic appeal in spaces. These glasses, produced using advanced technology, serve as highly resistant coverings against impacts and unexpected events, providing increased safety. One of the essential technologies in the production of tempered glass is thermal strengthening. This process involves heating the glass to an extremely high temperature, followed by rapid cooling. The result is a glass with a tightly compressed interior and a rapidly cooled, stronger exterior. As a result, tempered glass can withstand significant impact and, even if broken, shatters into small, harmless fragments.

- Perfect security: High resistance to impact and breakage

- Long-lasting beauty: Unmatched transparency and visual appeal

- High safety: Prevention of cracks and hazards due to breakage

- Widespread application: Used in doors, windows, and various buildings

- Variety in design and thickness: A suitable choice for all types of spaces and needs

Introduction to Laminated Glass

Laminated glass, produced with advanced technology, provides added safety in spaces by offering high resistance to impacts and sudden incidents. One notable feature of laminated glass is the use of PVB (polyvinyl butyral) film layers placed between the glass layers. These PVB films prevent the glass from shattering completely when broken, reducing the associated risks. Laminated glass production also involves thermal and pressure processes bonding and strengthening the different layers of glass and PVB film. This results in a glass that resists impact while allowing suitable light transmission and clarity. Laminated glass combines safety, beauty, and functionality in a unique way. These glasses add a distinctive elegance to spaces, ensuring a secure and protective environment.

- Break resistance: Laminated glass has a high break resistance due to the bonding of multiple glass layers with interlayered PVB film.

- High safety: The PVB film layers (polyvinyl butyral) in laminated glass prevent scattering and reduce risks associated with shattered glass.

- Thermal and acoustic performance: Laminated glass film layers help to minimize heat and sound transmission, maintaining a comfortable temperature and reducing noise in interior spaces.

- UV protection: The film layers in laminated glass protect against harmful UV radiation, preventing fading and degradation of the glass over time.

- Beauty and durability: Laminated glass can incorporate unique designs, colors, and textures while providing high durability, enhancing the visual appeal of spaces.

- Layer composition: Laminated glass is composed of two or more glass layers, bonded with PVB films. This layered structure enhances impact and break resistance.

- Versatile applications: Laminated glass is used in buildings, vehicles, furniture, and storefronts.

- Fire resistance: These glass types are fire-resistant and help contain the spread of flames.

- Diverse designs: Laminated glass is available in various designs and colors, enhancing the décor of any space.

- No scattering: If broken, laminated glass fragments stay attached to the film, preventing scattering.

Double- and Triple-Glazed Glass

Double- and triple-glazed glass is designed to optimize window performance. These glasses consist of two or three glass layers separated by an air or gas-filled space, which improves thermal and sound insulation. The gap between the layers is typically filled with gases like argon, which prevent heat transfer, thus reducing energy consumption. This airspace also helps reduce environmental noise and prevents it from entering the building.

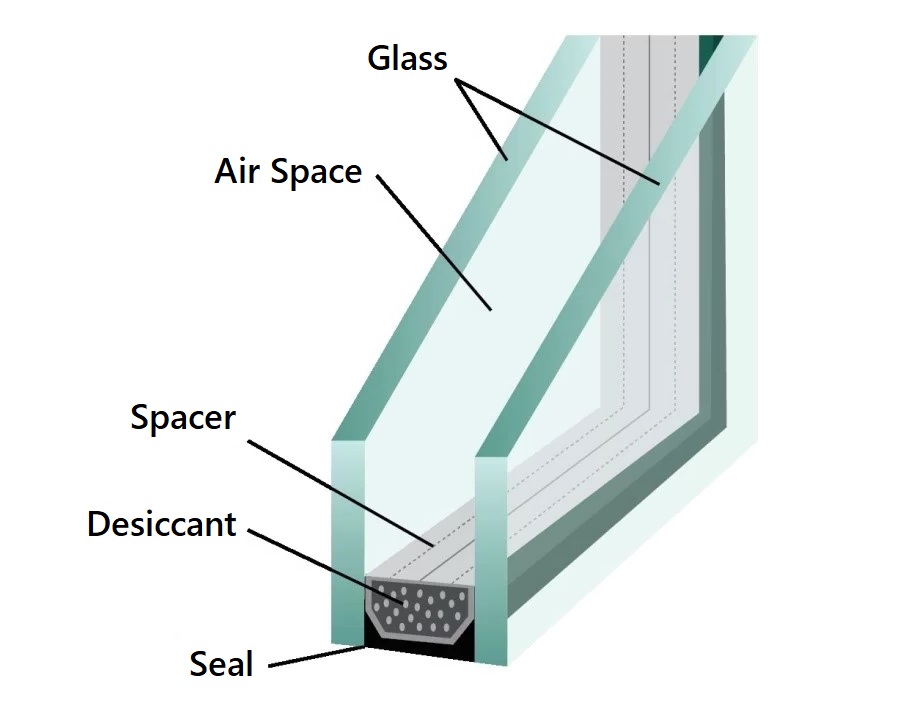

Structure of Double-Glazed Glass

Double-glazed glass, with a complex and precise structure, provides insulation against heat and noise. It is composed of two distinct layers separated by a middle gap. This gap is filled with argon gas, which has excellent insulating properties that significantly reduce heat transfer. Moisture-absorbing desiccants are placed around the glass edges to absorb any moisture trapped between the layers, preventing fogging and maintaining clarity. Additionally, sealants around the glass edges block air, dust, and moisture from entering between the glass layers, ensuring insulation effectiveness over time. This unique structure makes double-glazed glass an ideal choice for improving energy efficiency and comfort in residential and commercial spaces. Given the numerous benefits, investing in these glass types proves economical and cost-effective over time.

Features of Double- and Triple-Glazed Glass

- Thermal insulation: Significantly reduces energy loss, saving on heating and cooling costs.

- Acoustic insulation: Creates a quieter environment by reducing outside noise intrusion.

- UV protection: Reduces direct sunlight exposure, protecting interior furnishings.

- Prevents condensation: Enhances visibility and prevents gradual quality reduction in the glass over time

Due to their many benefits, these glass types are ideal for residential and commercial buildings, greatly enhancing comfort and quality of life. Choosing double- or triple-glazed glass depends on specific building requirements and the region's climate.